Investment casting, also known as lost-wax casting, is a manufacturing process used to create precise and complex metal parts. It is particularly useful for producing parts with intricate geometries and fine details that may be difficult or expensive to achieve using other methods like machining or die casting. Here’s an overview of the process:

Key Steps in the Investment Casting Process:

- Pattern Creation:

- The process begins by creating a pattern of the object to be cast. This pattern is typically made from a material such as wax or a similar substance.

- The pattern is an exact replica of the final part and is usually made using specialized molds or 3D printing technologies.

- Shell Building:

- The wax pattern is coated with a fine ceramic slurry. This involves dipping the pattern into a liquid ceramic material and then sprinkling it with a fine sand or powder.

- The coating process is repeated several times to build up a thick, hard shell around the pattern.

- The shell is then allowed to dry and harden.

- Wax Removal:

- The hardened shell, which now encases the wax pattern, is heated in a furnace or autoclave to melt and remove the wax, leaving behind a hollow ceramic shell.

- This is where the term “lost-wax” comes from, as the wax pattern is “lost” during this step.

- Mold Firing:

- The empty ceramic shell is then fired at high temperatures to further strengthen the mold and ensure it is free from any residual wax.

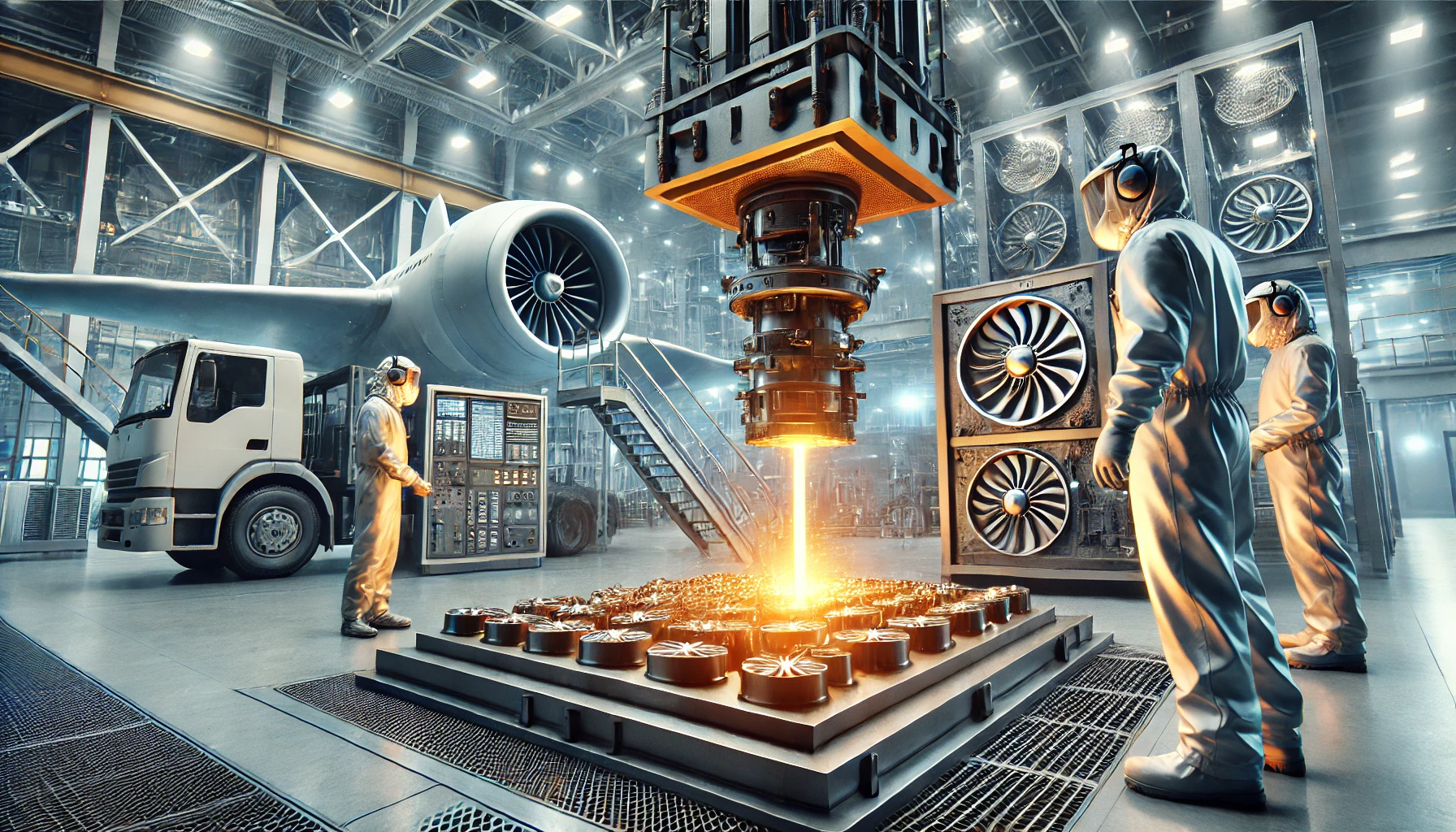

- Metal Pouring:

- Once the mold is prepared, molten metal is poured into the cavity created by the shell. The metal used can be various alloys, such as steel, bronze, or aluminum, depending on the desired properties of the final part.

- The molten metal fills the cavity left by the wax pattern and takes on the shape of the desired object.

- Shell Removal and Cleaning:

- After the metal has cooled and solidified, the ceramic shell is broken away, revealing the metal casting inside.

- The cast part is then cleaned to remove any residual shell material, and further post-processing steps like polishing, heat treating, or machining may be performed to meet exact specifications.

Advantages of Investment Casting:

- Precision: Investment casting can achieve very fine details and tight tolerances, often requiring little to no further machining.

- Complexity: It is ideal for producing complex geometries that are difficult or impossible to manufacture with other methods.

- Material Variety: A wide range of metals, including high-performance alloys, can be cast using this method.

- Surface Finish: The casting process produces smooth surface finishes, reducing the need for additional finishing operations.

Applications of Investment Casting:

- Aerospace: Components such as turbine blades, housings, and structural parts.

- Automotive: Parts like engine blocks, gears, and brackets.

- Medical Devices: Surgical instruments and implants.

- Art and Jewelry: Fine, detailed designs for custom jewelry pieces.

Disadvantages:

- Cost: The initial setup for investment casting can be expensive, especially for smaller production runs.

- Material Limitations: Not all materials are suitable for the process, particularly in extremely large or very high-volume production.

Overall, investment casting is an effective and versatile manufacturing method that offers high precision for producing complex and detailed metal parts across various industries.