We specialize in supplying high-quality investment castings and machined parts. Additionally, we offer comprehensive casting surface treatment services to meet your specific requirements.

Mirror Polishing

Mirror Polishing is a surface finishing process that achieves a smooth, highly reflective, and glossy finish on materials, often resembling a mirror. This technique is commonly applied to metals but can also be used on other materials like plastics or glass.

Key Features of Mirror Polishing

- Smooth Surface: Removes imperfections such as scratches, pits, and rough textures.

- Reflectivity: Produces a high-gloss, mirror-like shine.

- Durability: Enhances resistance to corrosion and wear by reducing surface roughness.

- Aesthetic Appeal: Often used to improve the visual appearance of the product.

Applications

- Aerospace and Automotive: Components like turbine blades, exhaust systems, and trim parts.

- Consumer Products: Jewelry, watches, kitchen utensils, and decorative items.

- Industrial Equipment: Machine parts, valves, and fittings.

- Medical Devices: Surgical instruments and implants for hygiene and aesthetics.

Mirror Polishing Process

- Preparation:

- Begin with rough polishing to remove large imperfections.

- Use abrasive tools like sanding belts or grinding wheels.

- Intermediate Polishing:

- Apply finer abrasives to further refine the surface.

- Common tools: abrasive pads, disks, or wheels.

- Finishing:

- Use polishing compounds like rouge or cerium oxide with a buffing wheel.

- Achieve a flawless, reflective finish.

- Cleaning:

- Clean the polished surface to remove residue or compounds.

- Inspect for uniformity and defects.

Benefits

- Enhanced Visual Appeal: Creates an attractive, professional look.

- Improved Performance: Reduces friction and wear in mechanical parts.

- Corrosion Resistance: Smooth surfaces are less prone to corrosion.

- Ease of Cleaning: Mirror-polished surfaces are easier to maintain.

Tools and Materials

- Abrasives: Sandpaper, emery cloth, grinding wheels.

- Polishing Compounds: Aluminum oxide, diamond paste, rouge.

- Equipment: Buffing machines, rotary tools, handheld polishers.

Dull Polishing parts / Satin Polishing parts

Dull Polishing and Satin Polishing are surface finishing techniques used to create a non-reflective, smooth, and uniform appearance on parts. These finishes are ideal for applications where aesthetics and practicality merge, offering a sleek, matte look while maintaining functionality.

Dull Polishing

- Description: Produces a matte, non-reflective surface with a soft texture.

- Appearance: Uniform, subdued finish with little to no gloss.

- Purpose: Often used to reduce glare, mask fingerprints, or create a subtle and understated aesthetic.

- Applications:

- Industrial machinery

- Automotive parts

- Household appliances

- Process:

- Use coarse abrasives to remove imperfections and surface irregularities.

- Apply finer abrasives for a uniform dull finish.

- Often completed without polishing compounds to maintain a matte effect.

Satin Polishing

- Description: Creates a smooth, silky finish with a low-level sheen, between dull and shiny.

- Appearance: Softly reflective, with visible but fine grain patterns.

- Purpose: Combines aesthetic appeal with practical benefits like fingerprint resistance and durability.

- Applications:

- Architectural hardware (door handles, fixtures)

- Medical devices

- Decorative components (jewelry, watches)

- Process:

- Start with sanding or brushing to remove surface irregularities.

- Use medium-grit abrasives to create a consistent, directional grain.

- Finish with finer abrasives or polishing pads for a satin sheen.

Comparison: Dull Polishing vs. Satin Polishing

| Feature | Dull Polishing | Satin Polishing |

|---|---|---|

| Reflectivity | Minimal, matte | Slight sheen, soft reflectivity |

| Texture | Uniform, no grain visible | Visible fine grain pattern |

| Aesthetic | Understated, functional | Sleek, elegant |

| Applications | Industrial, utility-focused | Decorative, semi-luxury |

| Durability | High resistance to wear | Similar with added elegance |

Benefits

- Durability: Both finishes enhance resistance to wear and tear.

- Aesthetic Appeal: Ideal for creating modern, professional, or minimalistic designs.

- Ease of Maintenance: Both finishes reduce the visibility of scratches and fingerprints compared to high-gloss surfaces.

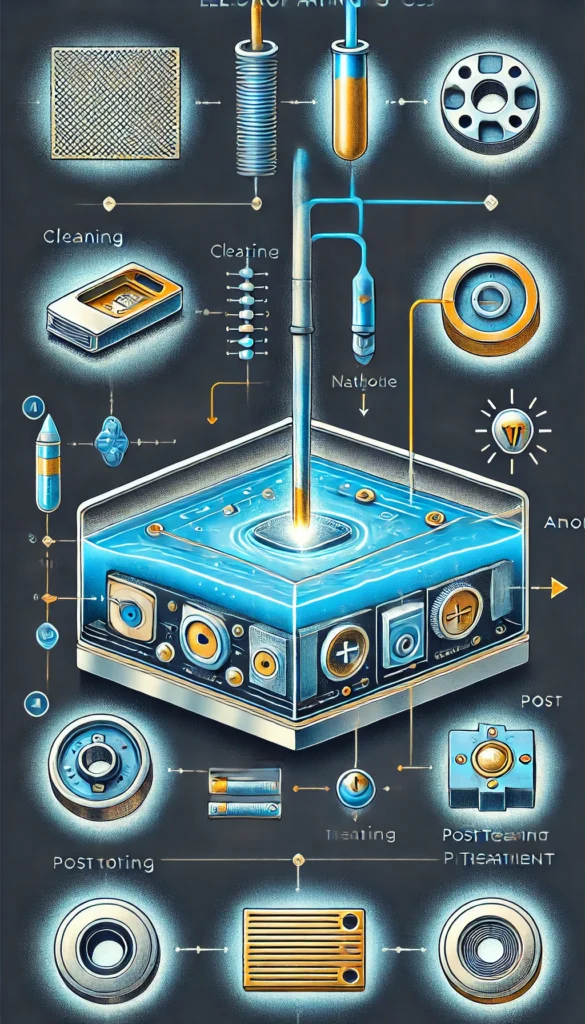

Electro Polishing

Electropolishing is a chemical and electrochemical process used to smooth, polish, and passivate the surface of metal parts. It removes a thin layer of material to enhance the surface finish, improve cleanliness, and provide corrosion resistance.

Key Features of Electropolishing

- Material Removal: Removes microscopic high points (peaks) to create a smooth, even surface.

- Improved Aesthetics: Produces a bright, reflective, and clean finish.

- Corrosion Resistance: Passivates the metal, forming a protective oxide layer.

- Hygiene and Cleanliness: Reduces the ability of contaminants to adhere to the surface.

How Electropolishing Works

- Setup: The metal part is submerged in an electrolyte solution (typically a mix of acids) and connected as the anode in an electrical circuit.

- Electric Current: A DC current passes through the part, dissolving surface imperfections.

- Selective Removal: Peaks are preferentially removed due to higher current density at raised points, resulting in a smoother surface.

- Rinse and Passivation: The part is rinsed, and a passive oxide layer forms, enhancing corrosion resistance.

Applications

- Medical Devices: Surgical instruments, implants, and equipment for enhanced cleanliness and biocompatibility.

- Food and Beverage: Processing equipment for hygiene and reduced bacterial adhesion.

- Aerospace and Automotive: Components requiring enhanced surface finish and durability.

- Semiconductor Industry: Parts used in cleanroom environments to prevent contamination.

Benefits of Electropolishing

- Surface Smoothing: Removes roughness and burrs for a uniform surface.

- Enhanced Corrosion Resistance: Forms a passive layer that protects against oxidation.

- Improved Cleanability: Reduces contamination risks by creating a smoother surface.

- Increased Aesthetic Appeal: Produces a bright, reflective, and professional finish.

- Deburring: Removes micro-burrs and sharp edges, improving safety and functionality.

Compatible Materials

Electropolishing is most effective on metals such as:

- Stainless steel

- Aluminum

- Copper and brass

- Nickel alloys

- Titanium

Comparison: Electropolishing vs. Mechanical Polishing

| Feature | Electropolishing | Mechanical Polishing |

|---|---|---|

| Process | Electrochemical | Abrasive or manual |

| Finish | Smooth, bright, reflective | Can be matte or glossy |

| Material Removal | Microscopic, uniform | Can be uneven |

| Hygiene | Superior (reduces contamination) | Moderate |

| Corrosion Resistance | High (passivation) | Moderate |

Limitations

- Cost: Requires specialized equipment and chemicals.

- Material Thickness: Removes a thin layer, so it may not be suitable for parts with tight dimensional tolerances.

- Material Compatibility: Not all metals are suitable for electropolishing.

Tumbling / Vibration Grinding parts

Tumbling and Vibration Grinding (also known as vibratory finishing) are mass finishing processes used to smooth, deburr, clean, and polish parts. These methods are particularly suitable for treating large quantities of small to medium-sized parts simultaneously, improving surface quality and preparing them for further processing or final use.

Tumbling

- Process:

- Parts and abrasive media are placed in a rotating barrel.

- As the barrel rotates, the media and parts rub against each other, removing imperfections.

- Best For:

- Parts with simple shapes.

- Heavier material removal or aggressive deburring.

- Finish:

- Produces a smooth or matte finish depending on the media used.

- Often used as a pre-polishing process.

- Applications:

- Metal castings, machined components, and jewelry.

- Advantages:

- Handles large batches cost-effectively.

- Can process heavier or bulkier parts.

- Disadvantages:

- Less precise than vibratory finishing.

- Longer cycle times.

Vibration Grinding (Vibratory Finishing)

- Process:

- Parts and abrasive media are placed in a vibrating bowl.

- The vibrations cause the media to flow over the parts, creating friction that smooths and polishes the surface.

- Best For:

- Delicate or intricately shaped parts.

- Producing consistent, precise finishes.

- Finish:

- Produces a fine, uniform finish with controlled media flow.

- Ideal for light deburring, polishing, and edge radiusing.

- Applications:

- Aerospace components, precision instruments, and parts with complex geometries.

- Advantages:

- Gentle on parts, preserving intricate details.

- Shorter cycle times compared to tumbling.

- Suitable for automated setups.

- Disadvantages:

- Limited to smaller, lighter parts.

- Less effective for aggressive material removal.

Comparison: Tumbling vs. Vibration Grinding

| Feature | Tumbling | Vibration Grinding |

|---|---|---|

| Motion | Rotational barrel | Vibrating bowl or tub |

| Material Removal | Aggressive | Controlled and gentle |

| Precision | Moderate | High |

| Cycle Time | Longer | Shorter |

| Part Size | Larger, bulkier parts | Smaller, more delicate parts |

Media Used

- Abrasive Media:

- Ceramic: For heavy deburring and aggressive cutting.

- Plastic: For softer materials or finer finishes.

- Polishing Media:

- Steel: For burnishing and high-gloss finishes.

- Corn Cob/Walnut Shell: For polishing and cleaning.

- Compounds:

- Added to enhance cleaning, lubrication, or corrosion resistance.

Applications

- Deburring: Removes sharp edges and burrs from machined or cast parts.

- Polishing: Achieves a smooth and aesthetically pleasing finish.

- Edge Radiusing: Rounds sharp edges for safety and improved performance.

- Surface Cleaning: Removes scale, rust, or contaminants.

Industries

- Automotive: Polishing engine components and gears.

- Aerospace: Finishing precision parts.

- Jewelry: Polishing and cleaning intricate designs.

- Manufacturing: Deburring and cleaning cast or machined parts.

Sand Blasting parts

Sand Blasting (also known as abrasive blasting) is a surface treatment process where abrasive materials are propelled at high speed onto a part’s surface using compressed air or water. This process removes rust, paint, scale, or other surface contaminants while providing a clean, textured, or matte finish.

Key Features of Sand Blasting

- Surface Preparation: Prepares surfaces for painting, coating, or bonding.

- Cleaning: Removes rust, grease, old paint, or other contaminants.

- Texturing: Creates a uniform surface texture for functional or aesthetic purposes.

- Versatility: Works on a variety of materials, including metals, plastics, wood, and glass.

Types of Sand Blasting

- Dry Sand Blasting:

- Traditional method using compressed air to propel abrasive material.

- Requires proper ventilation or containment to manage dust.

- Wet Sand Blasting:

- Mixes abrasive material with water.

- Reduces dust and heat buildup, making it ideal for delicate surfaces.

- Shot Blasting:

- Uses metallic abrasives (like steel shot or grit) for heavy-duty cleaning or peening.

- Bead Blasting:

- Uses glass beads for a smoother, satin finish and less aggressive surface treatment.

Applications

- Rust and Paint Removal:

- Cleans metal surfaces, restoring them to bare material.

- Common in automotive restoration and industrial equipment maintenance.

- Surface Texturing:

- Creates a matte or rough surface for aesthetic or functional purposes.

- Used for decorative glass etching or preparing metal for coatings.

- Deburring and Edge Radiusing:

- Smooths sharp edges or removes burrs from machined parts.

- Cleaning:

- Removes contaminants from molds, dies, and tools.

- Peening:

- Increases fatigue strength and stress resistance in metal parts.

Advantages

- Versatility: Suitable for a wide range of materials and applications.

- Efficiency: Quickly removes contaminants and prepares surfaces.

- Surface Customization: Allows control over texture, finish, and appearance.

- Eco-Friendly Options: Many abrasives are reusable and non-toxic (e.g., glass beads, walnut shells).

Common Abrasive Materials

- Silica Sand: Traditional abrasive, though now less common due to health concerns.

- Aluminum Oxide: Durable and aggressive, ideal for heavy-duty applications.

- Glass Beads: Produces a smooth, satin finish, often for decorative purposes.

- Steel Shot/Grit: For heavy cleaning, peening, or creating a rough surface.

- Plastic Media: Gentle on softer materials like plastics and composites.

- Walnut Shells/Corn Cob: Eco-friendly options for gentle cleaning and polishing.

Precautions

- Safety Gear:

- Wear protective equipment, such as a respirator, gloves, and goggles.

- Dust Management:

- Use proper ventilation or containment to manage dust and prevent inhalation.

- Surface Damage:

- Choose the right abrasive material and pressure to avoid over-aggression or part damage.

Industries

- Automotive: Restoring car parts, cleaning engine components, and preparing surfaces for painting.

- Construction: Cleaning building facades, bridges, and heavy equipment.

- Manufacturing: Prepping parts for coating or removing scale from castings.

- Art and Design: Glass etching, decorative metalwork, and engraving.

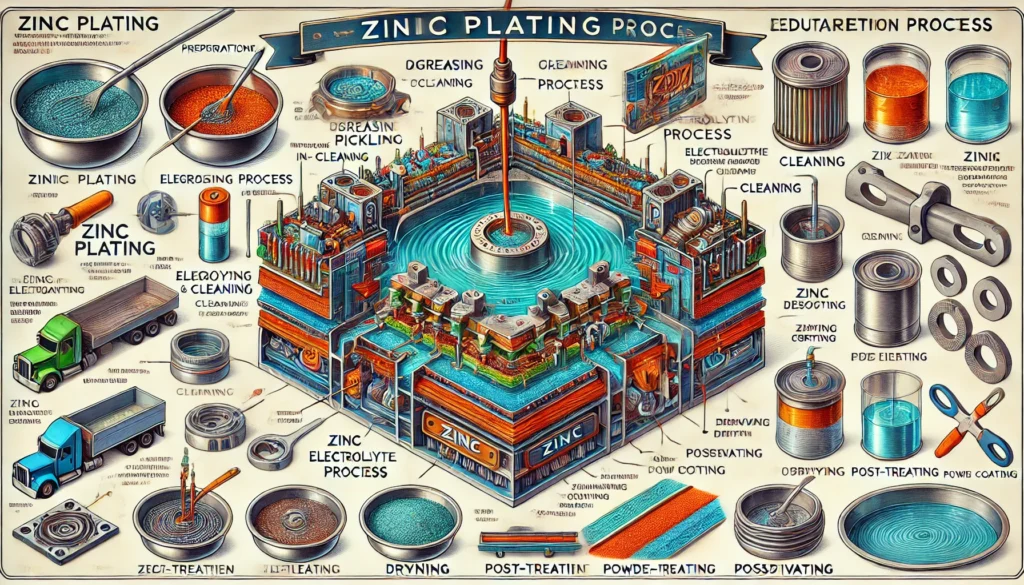

Zinc Plating parts

Zinc Plating is a surface finishing process that applies a thin layer of zinc onto metal parts to protect them from corrosion and enhance their appearance. This method is widely used in industries where components are exposed to moisture or harsh environments, as zinc serves as a sacrificial layer, corroding first to protect the underlying metal.

How Zinc Plating Works

- Preparation:

- Clean the surface of the part using degreasing, acid pickling, or abrasive cleaning to remove dirt, rust, and oil.

- Plating Process:

- The part is submerged in an electrolyte solution containing zinc salts.

- An electric current is passed through the solution, causing zinc ions to deposit onto the surface of the part (electroplating).

- Post-Treatment:

- Parts may undergo passivation (chromate conversion coating) to further improve corrosion resistance and provide specific finishes.

- Rinsing and drying finalize the process.

Types of Zinc Plating

- Barrel Plating:

- Suitable for small parts like screws, nuts, and bolts.

- Parts are tumbled in a rotating barrel during plating.

- Rack Plating:

- Ideal for larger or more delicate parts.

- Parts are fixed on racks to ensure even plating and avoid damage.

- Continuous Plating:

- Used for wires, tubes, or strip materials in a continuous process.

Finishes and Colors

- Clear (Blue) Zinc:

- Standard finish, offering moderate corrosion resistance with a bright appearance.

- Yellow Zinc:

- Provides enhanced corrosion protection and a golden hue.

- Black Zinc:

- Corrosion-resistant and aesthetic, often used in automotive applications.

- Olive Drab Zinc:

- Military-grade corrosion resistance with a greenish finish.

Applications

- Automotive: Fasteners, brackets, and under-the-hood components.

- Construction: Hardware like screws, nails, and bolts.

- Electrical: Components exposed to moisture or high humidity.

- Consumer Goods: Household appliances and furniture hardware.

Benefits of Zinc Plating

- Corrosion Protection: Zinc acts as a sacrificial coating, delaying rust on the base material.

- Cost-Effective: Economical compared to other plating options like nickel or chrome.

- Enhanced Appearance: Provides a clean, professional finish in various colors.

- Versatility: Suitable for a wide range of metals and industries.

- Improved Durability: Resistant to wear and environmental damage when combined with post-treatments.

Comparison: Zinc Plating vs. Other Coatings

| Feature | Zinc Plating | Galvanizing | Chrome Plating |

|---|---|---|---|

| Process | Electroplating | Hot-dipping | Electroplating |

| Corrosion Resistance | Moderate to high (with passivation) | Very high | Low unless combined |

| Appearance | Bright, colorful options | Matte, industrial look | Mirror-like finish |

| Applications | Precision parts | Structural steel | Decorative parts |

Limitations

- Thickness: Thin coating may wear off in high-friction or abrasive environments.

- Base Metal Compatibility: Primarily used on steel and iron; less effective on other materials.

- Environmental Concerns: Hexavalent chromate used in some post-treatments is toxic, though trivalent chromate is a safer alternative.

Black Oxide parts

Black Oxide Parts refer to components treated with a black oxide coating, a chemical conversion process that creates a thin, black, and mildly protective layer on the surface of metals. This process is widely used for enhancing appearance, reducing light reflection, improving corrosion resistance (when sealed), and providing mild wear resistance.

Features of Black Oxide Parts

- Appearance:

- A uniform black finish, often matte, with an understated and professional look.

- Corrosion Resistance:

- Effective when combined with a post-treatment sealant (e.g., oil or wax) that enhances resistance to rust and moisture.

- Dimensional Stability:

- The black oxide layer is extremely thin (typically 0.00002 to 0.0001 inches) and does not significantly alter the dimensions of the part, making it ideal for precision components.

- Wear Reduction:

- Provides slight lubrication that reduces friction between mating parts.

- Temperature Resistance:

- Withstands high temperatures without degradation or peeling.

Applications of Black Oxide Parts

- Automotive Industry:

- Fasteners, engine components, and brackets where aesthetic and mild corrosion protection are important.

- Firearms and Tools:

- Gun barrels, hand tools, and blades to reduce glare and prevent rust.

- Machinery and Equipment:

- Gears, shafts, and precision parts that require minimal dimensional change.

- Aerospace:

- Components like fittings and housings where appearance and slight corrosion resistance are essential.

- Consumer Goods:

- Decorative hardware, kitchen utensils, and custom fixtures.

Advantages of Black Oxide Coating

- Economical:

- Cost-effective for large production runs compared to other finishing processes.

- Aesthetic Appeal:

- Provides a clean, uniform, and low-reflectivity finish.

- Environmental Impact:

- Generally considered environmentally friendly, especially cold and mid-temperature processes.

- Compatible with Tight Tolerances:

- The thin coating layer is ideal for parts where precise dimensions are critical.

- Enhanced Durability:

- The sealant provides additional wear and corrosion resistance.

Types of Black Oxide Coatings

- Hot Black Oxide:

- Performed at high temperatures (around 285°F / 140°C).

- Produces a durable and high-quality black finish.

- Cold Black Oxide:

- Room-temperature process; easier and faster but less durable.

- Often used for decorative purposes.

- Mid-Temperature Black Oxide:

- Operates at around 200°F (93°C).

- Balances ease of application with durability and corrosion resistance.

Comparison: Black Oxide vs. Other Surface Treatments

| Feature | Black Oxide | Zinc Plating | Powder Coating |

|---|---|---|---|

| Thickness | Very thin, maintains tolerances | Moderate, adds thickness | Thicker, durable layer |

| Corrosion Resistance | Moderate (with oil/wax) | High | Very high |

| Aesthetic | Matte black finish | Shiny or colorful finishes | Wide variety of finishes |

| Cost | Low to moderate | Moderate | Higher |

Limitations of Black Oxide

- Limited Corrosion Protection:

- Without a sealant, corrosion resistance is minimal, especially in wet environments.

- Material Compatibility:

- Primarily used on ferrous metals (steel and iron). Limited use on stainless steel, copper, and brass.

- Surface Preparation:

- Requires thorough cleaning and preparation for optimal results.

Maintenance of Black Oxide Parts

- Apply Protective Sealant:

- Periodically reapply oil or wax to maintain corrosion resistance.

- Clean with Care:

- Avoid harsh chemicals or abrasive cleaning tools that might remove the sealant or oxide layer.

Pickling parts

Pickling is a chemical treatment process used to remove impurities such as rust, scale, or oxides from metal surfaces, typically after forging, welding, or heat treatment. This process involves immersing the parts in an acid solution to clean the surface and prepare it for further finishing, coating, or fabrication.

How Pickling Works

- Preparation:

- The part is cleaned to remove oil, grease, or dirt, ensuring effective acid contact during pickling.

- Pickling Process:

- The part is submerged in an acidic solution (commonly hydrochloric acid, sulfuric acid, or nitric acid).

- The acid reacts with the metal oxides, dissolving them and leaving a clean, bare surface.

- Rinsing:

- After pickling, the part is thoroughly rinsed with water to remove residual acid.

- Optional Neutralization:

- Some processes involve a neutralizing step to counteract residual acidity and prevent corrosion.

Applications of Pickling

- Steel and Iron:

- Removes mill scale and rust from hot-rolled or heat-treated parts.

- Stainless Steel:

- Removes discoloration, heat tint, and chromium-depleted layers from welding or heat treatment.

- Non-Ferrous Metals:

- Cleans brass, copper, and aluminum components.

- Preparation for Coatings:

- Cleans surfaces to ensure better adhesion for coatings like paint, powder, or plating.

- Post-Manufacturing Cleaning:

- Used on pipes, fittings, tanks, and structural components to restore cleanliness.

Benefits of Pickling

- Thorough Cleaning:

- Effectively removes oxides, rust, and scale that mechanical cleaning methods might miss.

- Surface Preparation:

- Provides a clean, reactive surface ideal for further processing or finishing.

- Preserves Metal Properties:

- Does not significantly alter the dimensions or properties of the base metal.

- Improves Aesthetic:

- Restores a uniform, clean surface, especially important for visible parts.

Types of Pickling Processes

- Immersion Pickling:

- Parts are submerged in an acid bath, suitable for small or batch-processed components.

- Spray Pickling:

- Acid is sprayed onto large or immovable parts.

- Paste Pickling:

- Acidic paste is applied to specific areas, often on stainless steel welds, for localized treatment.

- Electrolytic Pickling:

- Combines electrical current with acid treatment for more efficient cleaning.

Acid Solutions Used

- Hydrochloric Acid (HCl):

- Common for carbon steels and iron, effective for removing mill scale.

- Sulfuric Acid (H₂SO₄):

- Economical and widely used for general cleaning.

- Nitric and Hydrofluoric Acid Mix:

- Often used for stainless steel to remove chromium oxides and restore passivation.

- Phosphoric Acid:

- Milder acid, sometimes used for light rust removal and passivation.

Precautions

- Safety:

- Use appropriate personal protective equipment (PPE), including gloves, goggles, and acid-resistant clothing.

- Ensure proper ventilation to handle fumes.

- Environmental Concerns:

- Properly dispose of spent acid solutions to comply with environmental regulations.

- Hydrogen Embrittlement:

- Prolonged exposure to acid can cause hydrogen to diffuse into the metal, making it brittle. Mitigate by controlling exposure time or performing post-pickling treatments.

Industries Using Pickling

- Automotive: Cleaning engine components, frames, and suspension parts.

- Aerospace: Removing oxides and contaminants from precision parts.

- Construction: Cleaning structural steel, pipes, and tanks.

- Manufacturing: Preparing parts for coating or improving weld quality.

Pickling vs. Other Cleaning Methods

| Feature | Pickling | Sand Blasting | Tumbling/Vibration Grinding |

|---|---|---|---|

| Method | Chemical treatment | Abrasive cleaning | Mechanical cleaning |

| Material Removal | Oxides, rust, and scale | Surface contaminants and paint | Burrs and surface smoothing |

| Surface Effect | Smooth, clean surface | Matte, rough texture | Smooth, polished finish |

| Application | Precision cleaning | Heavy-duty or decorative cleaning | Deburring and polishing |

Powder Coating

Powder Coating is a durable and versatile finishing process that applies a dry, electrostatically charged powder to metal (and some non-metal) surfaces. The powder is then cured under heat, forming a smooth, hard, and protective layer. It is widely used for decorative and functional purposes across various industries.

How Powder Coating Works

- Preparation:

- The surface is cleaned and pre-treated to remove dirt, grease, rust, or other contaminants.

- Common pre-treatments include sandblasting, chemical cleaning, or phosphate coating.

- Application:

- The powder, made of finely ground particles of resin, pigment, and additives, is applied using an electrostatic spray gun.

- The powder adheres to the part due to the electrostatic charge.

- Curing:

- The coated part is placed in a curing oven at 300–400°F (150–200°C).

- Heat melts the powder, forming a continuous film that bonds to the surface as it cools.

Types of Powder Coating

- Thermoset Powder Coating:

- Forms a permanent, heat-resistant bond that cannot be remelted after curing.

- Common resins: epoxy, polyester, and polyurethane.

- Thermoplastic Powder Coating:

- Can be reheated and remelted.

- Provides a thicker coating and high durability (e.g., PVC or nylon-based powders).

Advantages of Powder Coating

- Durability:

- Highly resistant to chipping, scratching, fading, and corrosion.

- Environmentally Friendly:

- Contains no solvents, resulting in minimal volatile organic compounds (VOCs).

- Wide Range of Finishes:

- Available in various colors, textures (smooth, matte, glossy), and effects (metallic, wrinkle, or hammered finishes).

- Cost-Effective:

- Oversprayed powder can be collected and reused, reducing waste.

- Uniform Coating:

- Provides a consistent and thick layer without running or dripping, unlike liquid paint.

- Corrosion Resistance:

- Excellent protection against moisture, chemicals, and UV radiation when properly applied.

Applications of Powder Coating

- Automotive:

- Wheels, engine parts, chassis components, and trim pieces.

- Consumer Goods:

- Appliances (refrigerators, ovens), furniture, and outdoor equipment.

- Construction:

- Railings, doors, windows, and structural steel.

- Electronics:

- Casings and enclosures for electrical equipment.

- Industrial Equipment:

- Tools, machinery, and agricultural equipment.

Comparison: Powder Coating vs. Liquid Painting

| Feature | Powder Coating | Liquid Painting |

|---|---|---|

| Application | Dry powder with electrostatic charge | Liquid spray |

| Durability | Highly durable and scratch-resistant | Less durable, prone to wear |

| Environmental Impact | Low VOC emissions | High VOC emissions |

| Finish Options | Wide variety, consistent layers | Wide variety, but less uniform |

| Cost | Higher initial cost, long-term savings | Lower initial cost |

Limitations of Powder Coating

- Initial Equipment Costs:

- Requires specialized equipment (e.g., spray guns, curing ovens).

- Material Limitations:

- Primarily used on metal; limited options for plastics and wood unless specially prepared.

- Complex Shapes:

- Difficult to coat parts with recessed areas or sharp corners uniformly.

- Color Change Challenges:

- Switching colors can be time-consuming due to equipment cleaning.

Maintenance of Powder-Coated Parts

- Cleaning:

- Use mild soap and water to clean the surface; avoid abrasive cleaners or tools.

- Inspection:

- Periodically check for chips or damage and touch up with compatible coatings to maintain protection.

Zinc Plating

Zinc Plating is an electroplating process that applies a thin layer of zinc to the surface of metal parts, primarily to provide corrosion resistance. The zinc layer acts as a sacrificial barrier, protecting the underlying metal from oxidation. It is widely used in various industries for both functional and decorative purposes.

How Zinc Plating Works

- Preparation:

- The part is thoroughly cleaned to remove grease, oil, and oxides.

- Cleaning methods include degreasing, pickling, and abrasive blasting.

- Electroplating Process:

- The part is submerged in an electrolyte solution containing zinc ions.

- A direct current passes through the solution, causing zinc ions to deposit onto the metal surface.

- Post-Treatment:

- Parts are rinsed, dried, and often treated with a passivation layer or chromate coating to enhance corrosion resistance and achieve desired colors (e.g., clear, yellow, black, or olive drab finishes).

Types of Zinc Plating

- Acid Zinc Plating:

- Provides a bright and smooth finish.

- Commonly used for decorative purposes.

- Alkaline Zinc Plating:

- Offers better coverage in recessed areas.

- Preferred for parts with complex geometries.

- Cyanide Zinc Plating (rarely used):

- Historical method, now largely replaced due to environmental concerns.

Benefits of Zinc Plating

- Corrosion Resistance:

- Protects the base metal by acting as a sacrificial anode.

- Aesthetic Appeal:

- Provides a bright, clean finish with options for different colors.

- Cost-Effective:

- Economical for large-scale production.

- Adhesion for Paint/Coatings:

- Acts as a primer layer for additional coatings.

- Extended Part Lifespan:

- Reduces maintenance and replacement costs in corrosive environments.

Applications of Zinc Plating

- Automotive Industry:

- Fasteners, brackets, and engine components.

- Construction:

- Nuts, bolts, and structural steel parts exposed to the environment.

- Electrical Industry:

- Connectors, enclosures, and fittings.

- Consumer Goods:

- Hardware, tools, and decorative items.

- Industrial Equipment:

- Machinery parts and agricultural tools.

Comparison: Zinc Plating vs. Other Coatings

| Feature | Zinc Plating | Galvanizing | Powder Coating |

|---|---|---|---|

| Thickness | Thin (5–25 microns) | Thicker (50–200 microns) | Moderate to thick |

| Corrosion Resistance | Moderate | High | Very high |

| Aesthetic | Bright, clean finish | Matte, rough texture | Wide variety of finishes |

| Durability | Moderate, sacrificial protection | Very durable | Extremely durable |

| Cost | Low to moderate | Higher than zinc plating | Higher initial investment |

Limitations of Zinc Plating

- Limited Thickness:

- Not suitable for environments requiring heavy-duty corrosion resistance.

- Hydrogen Embrittlement:

- Can occur in high-strength steels, requiring a baking process to reduce risks.

- Environmental Concerns:

- Plating process involves hazardous chemicals that require proper handling and disposal.

- Surface Wear:

- Zinc is softer than other coatings and may wear down over time in abrasive conditions.

Common Post-Treatments for Zinc Plated Parts

- Passivation/Chromate Conversion Coating:

- Enhances corrosion resistance and provides a variety of finishes (e.g., clear, yellow, black).

- Sealants:

- Adds an extra layer of protection, improving durability.

- Heat Treatment:

- Used to mitigate hydrogen embrittlement in high-strength materials.

Maintenance of Zinc-Plated Parts

- Cleaning:

- Use non-abrasive cleaners to maintain the surface finish.

- Inspection:

- Regularly check for signs of wear or corrosion, especially in aggressive environments.

- Replating:

- Consider reapplying zinc plating if the coating is significantly worn.

Chrome Plating

Chrome Plating, also known as chromium plating, is a surface finishing process in which a thin layer of chromium is electroplated onto a substrate, typically metal. This process enhances the part’s appearance, increases its wear resistance, and improves corrosion resistance. Chrome plating is widely used in automotive, industrial, and decorative applications.

How Chrome Plating Works

- Preparation:

- The substrate is thoroughly cleaned to remove contaminants like oil, grease, and dirt.

- Mechanical or chemical surface preparation (e.g., polishing, grinding) ensures smoothness for better adhesion.

- Electroplating Process:

- The part is immersed in a chromic acid-based electrolyte bath.

- A direct current passes through, causing chromium ions to deposit onto the surface.

- Curing and Polishing:

- After plating, the part is rinsed, dried, and sometimes polished to achieve the desired finish.

Types of Chrome Plating

- Decorative Chrome Plating:

- Thin layer of chromium (0.005–0.05 mm).

- Applied over nickel plating for aesthetic purposes.

- Commonly used on automotive trim, appliances, and fixtures.

- Hard Chrome Plating:

- Thicker layer of chromium (0.1–0.5 mm).

- Designed for industrial and functional purposes, such as wear and corrosion resistance.

- Used on hydraulic cylinders, engine components, and tools.

Benefits of Chrome Plating

- Aesthetic Appeal:

- Creates a bright, reflective, and mirror-like finish.

- Corrosion Resistance:

- Protects the underlying material from moisture, chemicals, and rust.

- Wear Resistance:

- Provides a hard, durable surface that resists abrasion.

- Extended Lifespan:

- Enhances the durability and performance of components.

- Heat Resistance:

- Withstands high temperatures without degradation.

Applications of Chrome Plating

- Automotive Industry:

- Grilles, bumpers, rims, exhaust pipes, and engine parts.

- Aerospace:

- Landing gear components, turbine blades, and structural parts.

- Industrial Equipment:

- Hydraulic rods, dies, and molds for wear and friction reduction.

- Consumer Goods:

- Bathroom fixtures, furniture, and decorative items.

- Marine Applications:

- Corrosion-resistant finishes for ship components and fittings.

Comparison: Chrome Plating vs. Other Coatings

| Feature | Chrome Plating | Nickel Plating | Powder Coating |

|---|---|---|---|

| Finish | Bright, mirror-like | Satin to bright | Wide variety of finishes |

| Thickness | Thin to thick | Thin | Moderate to thick |

| Durability | Very durable, wear-resistant | Moderate | Extremely durable |

| Corrosion Resistance | High | High | Very high |

| Cost | Moderate to high | Lower than chrome | Moderate to high |

Limitations of Chrome Plating

- Environmental Concerns:

- Chromium plating involves hazardous chemicals (e.g., hexavalent chromium), requiring strict environmental controls and disposal procedures.

- Cracking and Brittleness:

- Thick layers can become brittle and prone to cracking under stress.

- Cost:

- More expensive than many other surface treatments due to complex processes and environmental regulations.

- Surface Preparation:

- Requires meticulous preparation to achieve uniform adhesion and finish.

- Repair Challenges:

- Damaged chrome plating is difficult to repair and often requires stripping and replating.

Maintenance of Chrome-Plated Parts

- Regular Cleaning:

- Use mild soap and water or a chrome-specific cleaner to remove dirt and prevent dulling.

- Polishing:

- Apply non-abrasive polishes to maintain the reflective finish.

- Avoid Harsh Conditions:

- Minimize exposure to corrosive environments, as the base material can corrode if the chrome layer is damaged.

- Inspection:

- Regularly inspect for signs of pitting, cracking, or peeling.

Alternatives to Chrome Plating

- Nickel Plating:

- Offers similar corrosion resistance with a less reflective finish.

- Powder Coating:

- Provides a broader range of finishes and thicker coatings with better environmental credentials.

- PVD Coating:

- Environmentally friendly and offers a range of colors and finishes.

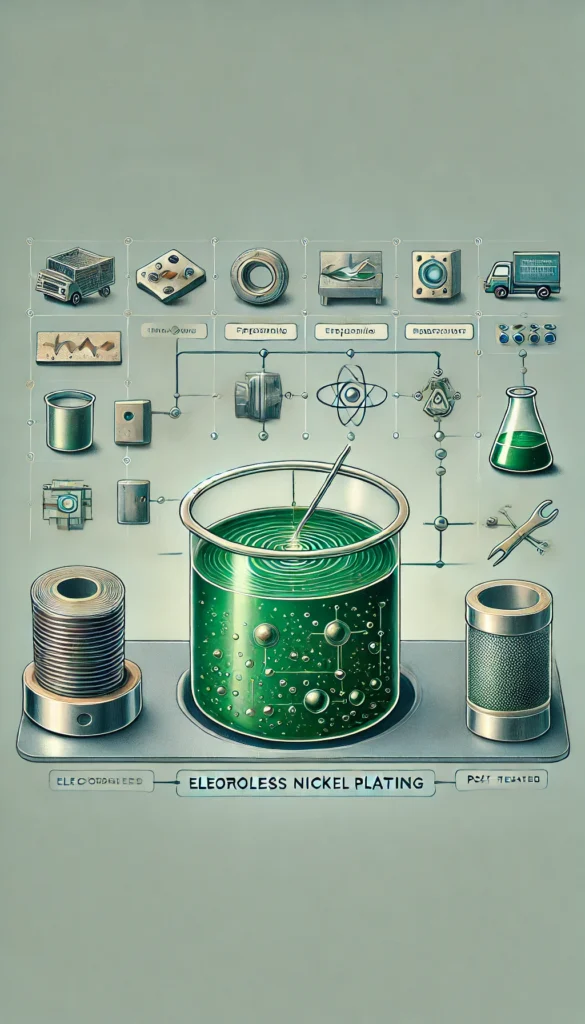

Nickel Plating

Nickel Plating is an electrochemical or electroless process that deposits a layer of nickel onto a metal or plastic substrate. It enhances corrosion resistance, improves wear resistance, and provides an attractive appearance. Nickel plating is widely used in industrial, automotive, aerospace, and decorative applications.

Types of Nickel Plating

- Electroplated Nickel (Electrolytic Nickel Plating):

- A process where nickel is deposited on a substrate using an electric current in a nickel electrolyte solution.

- Common for both decorative and functional applications.

- Electroless Nickel Plating:

- A chemical process that deposits nickel without an electric current.

- Known for its uniform coating, even on complex shapes, and superior corrosion resistance.

How Nickel Plating Works

Electroplated Nickel:

- Preparation:

- The part is cleaned to remove contaminants.

- Pre-treatment includes degreasing, pickling, and sometimes sandblasting.

- Electroplating Process:

- The part is immersed in a nickel electrolyte bath.

- An electric current causes nickel ions to deposit on the part’s surface.

- Post-Treatment:

- Parts are rinsed, dried, and sometimes polished for a desired finish.

Electroless Nickel:

- Preparation:

- Similar cleaning and pre-treatment as electroplating.

- Plating Process:

- The part is immersed in a solution with nickel salts and a reducing agent (e.g., sodium hypophosphite).

- A chemical reaction deposits nickel uniformly over the part.

- Curing:

- The part may be heat-treated to improve hardness and adhesion.

Benefits of Nickel Plating

- Corrosion Resistance:

- Protects substrates from rust and environmental damage.

- Wear Resistance:

- Improves the part’s ability to withstand friction and abrasion.

- Uniform Coating (Electroless Nickel):

- Deposits evenly on complex shapes and internal surfaces.

- Improved Aesthetic:

- Provides a bright, smooth, or matte finish for decorative purposes.

- Conductivity:

- Nickel plating enhances electrical conductivity for certain applications.

Applications of Nickel Plating

- Automotive:

- Components like bumpers, grilles, and engine parts for durability and aesthetics.

- Aerospace:

- Protective coatings for structural parts exposed to harsh environments.

- Electronics:

- Contacts, connectors, and printed circuit boards (PCBs).

- Industrial Machinery:

- Gears, shafts, and molds for wear and corrosion resistance.

- Consumer Goods:

- Bathroom fixtures, kitchen utensils, and decorative hardware.

Comparison: Electroless vs. Electroplated Nickel

| Feature | Electroless Nickel | Electroplated Nickel |

|---|---|---|

| Coating Uniformity | High, even on complex shapes | Variable, depends on geometry |

| Corrosion Resistance | Excellent | Moderate |

| Adhesion | Strong | Good |

| Hardness | Can be improved by heat treatment | Lower than electroless nickel |

| Cost | Higher | Lower |

Advantages of Nickel Plating

- Customizable Finish:

- Available in various finishes (bright, matte, or satin) to suit aesthetic needs.

- Enhanced Performance:

- Improves part longevity in demanding environments.

- Compatibility:

- Suitable for metals like steel, copper, brass, and aluminum, as well as certain plastics.

- Pre-Coating Layer:

- Often used as a base layer for chrome plating or other coatings.

Limitations of Nickel Plating

- Environmental Concerns:

- Nickel solutions contain hazardous chemicals, requiring proper handling and disposal.

- Hydrogen Embrittlement:

- Can occur in high-strength steels, needing post-plating heat treatment.

- Cost:

- Electroless nickel is more expensive due to the chemicals and process control required.

- Surface Preparation:

- Requires thorough cleaning for proper adhesion and uniformity.

Maintenance of Nickel-Plated Parts

- Cleaning:

- Use non-abrasive cleaners and soft cloths to avoid scratching.

- Inspection:

- Regularly check for damage, as exposed substrate can corrode quickly.

- Avoid Harsh Conditions:

- Limit exposure to acidic or highly alkaline environments unless additional coatings are applied.

Applications in Specific Industries

- Medical:

- Surgical tools and implants, benefiting from smooth, corrosion-resistant coatings.

- Oil & Gas:

- Coating of pipelines and valves for resistance to wear and harsh chemicals.

- Military:

- Components for defense systems requiring durability and precision.

Electroplate

Electroplating is a process that uses electrical current to deposit a thin layer of metal onto the surface of a substrate. This technique improves the part’s properties, such as corrosion resistance, wear resistance, electrical conductivity, or aesthetic appearance. Electroplating is widely used in industries like automotive, aerospace, electronics, and jewelry.

How Electroplating Works

- Preparation:

- The part (substrate) is thoroughly cleaned and degreased to remove contaminants.

- Surface preparation may include acid cleaning, abrasive blasting, or polishing.

- Electroplating Process:

- The part to be plated is connected to the negative terminal of a power source (cathode).

- A metal (e.g., nickel, copper, chromium) is connected to the positive terminal (anode).

- Both are submerged in an electrolyte solution containing ions of the plating metal.

- When current passes through the solution, metal ions are reduced and deposited onto the substrate’s surface.

- Post-Treatment:

- Rinsing, drying, and sometimes additional polishing or coating to achieve the desired finish.

Types of Electroplating

- Decorative Plating:

- Used to enhance appearance (e.g., chrome plating for a bright, reflective finish).

- Functional Plating:

- Improves specific properties like corrosion resistance, wear resistance, or electrical conductivity.

- Examples: Gold plating for electrical components, zinc plating for rust protection.

- Hard Plating:

- Produces a thick, durable coating for heavy-duty applications (e.g., hard chrome plating on machinery parts).

Benefits of Electroplating

- Corrosion Resistance:

- Protects the base metal by providing a barrier against environmental exposure.

- Improved Durability:

- Enhances wear resistance and extends the component’s lifespan.

- Aesthetic Enhancement:

- Provides a smooth, shiny, or textured finish for decorative purposes.

- Electrical Conductivity:

- Certain metals (e.g., gold, silver) improve the conductivity of electronic components.

- Reduced Friction:

- Plating materials like nickel can reduce surface friction in moving parts.

Common Electroplating Metals

- Gold:

- High conductivity, corrosion resistance, and aesthetic appeal.

- Used in electronics, jewelry, and luxury items.

- Silver:

- Excellent conductivity and antimicrobial properties.

- Used in electronics, cutlery, and medical devices.

- Copper:

- Good conductivity and adhesion.

- Often used as an undercoat or for electrical components.

- Nickel:

- Corrosion and wear resistance with decorative finishes.

- Used in automotive parts, coins, and consumer goods.

- Chromium:

- Bright, reflective, and highly durable.

- Common in automotive and decorative applications.

- Zinc:

- Sacrificial coating for corrosion protection.

- Widely used in fasteners and structural components.

Applications of Electroplating

- Automotive Industry:

- Chrome plating for bumpers and trim, zinc plating for corrosion-resistant fasteners.

- Aerospace:

- Nickel and cadmium plating for corrosion and wear resistance in extreme conditions.

- Electronics:

- Gold and silver plating for connectors, switches, and circuit boards.

- Jewelry:

- Decorative plating with gold, silver, or rhodium for a polished finish.

- Industrial Equipment:

- Hard chrome plating for hydraulic cylinders, molds, and tools.

Advantages of Electroplating

- Customizable:

- A wide range of metals and finishes can be tailored to specific needs.

- Cost-Effective:

- A thin layer of a precious or expensive metal can be applied instead of solid components.

- Versatility:

- Suitable for a wide variety of materials, including metals, plastics (after special preparation), and ceramics.

Limitations of Electroplating

- Environmental Concerns:

- The process generates hazardous waste and requires strict disposal methods.

- Hydrogen Embrittlement:

- Can occur in high-strength steels, leading to brittle failure if not addressed with post-plating heat treatment.

- Surface Preparation:

- Requires meticulous cleaning and preparation for proper adhesion and finish.

- Uniformity Issues:

- Complex shapes may experience uneven plating in recessed areas.

Maintenance of Electroplated Parts

- Cleaning:

- Use mild soap and water or a non-abrasive cleaner to maintain the finish.

- Inspection:

- Regularly check for signs of wear, peeling, or corrosion, especially in harsh environments.

- Avoid Abrasion:

- Minimize contact with abrasive materials that could damage the coating.

Alternatives to Electroplating

- Electroless Plating:

- A chemical deposition process for more uniform coatings.

- Powder Coating:

- Durable and environmentally friendly, with a wide range of finishes.

- Anodizing:

- For aluminum parts, improving corrosion resistance and aesthetics.