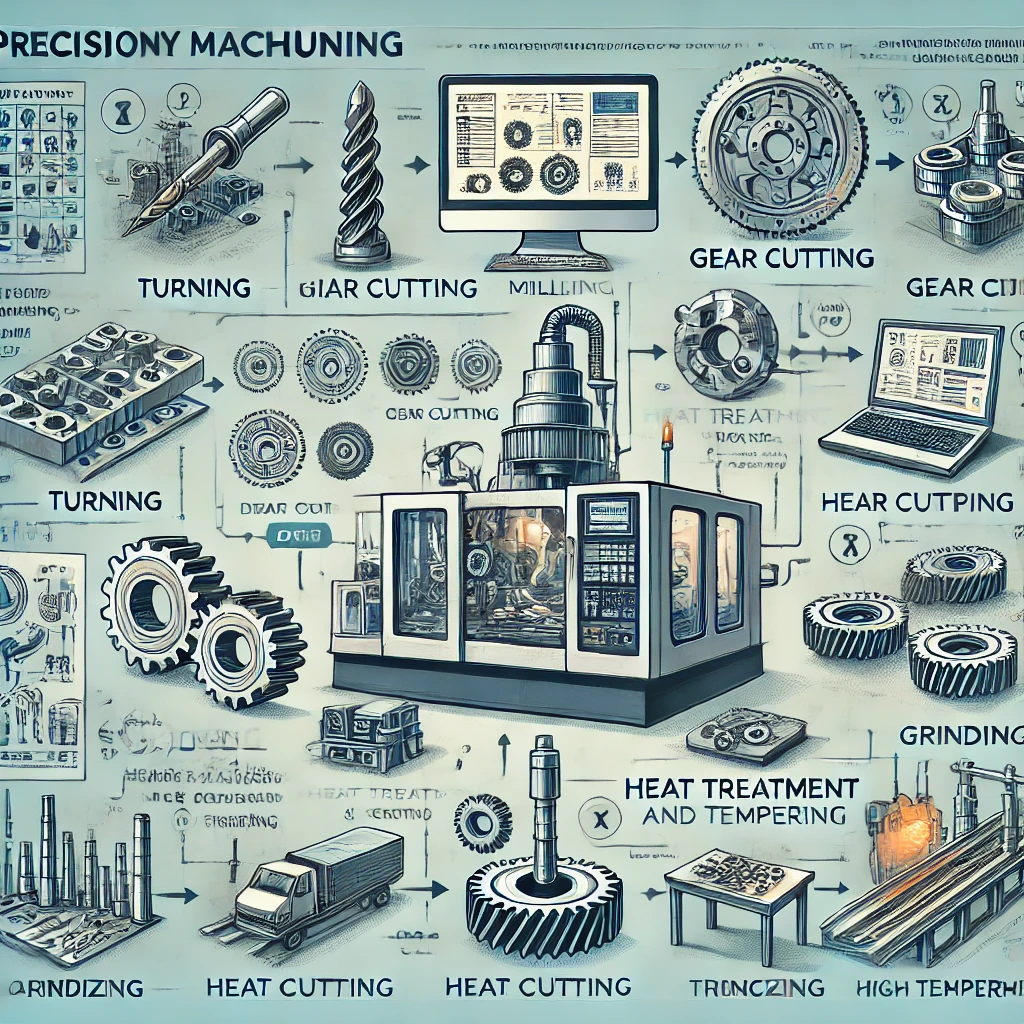

Precision machining is a highly specialized manufacturing process designed to produce components with tight tolerances, intricate designs, and excellent surface finishes. The process involves the removal of material from a workpiece using advanced tools and machines, including:

Key Processes:

- Turning: Rotating the workpiece while a cutting tool removes material, shaping it into cylindrical or conical forms.

- Milling: Using rotary cutters to remove material from the workpiece, creating precise shapes, slots, or contours.

- Drilling: Creating holes with high accuracy using drill bits.

- Gear Cutting: Producing gears with precise dimensions and profiles.

- Honing: Enhancing surface finish and dimensional accuracy of bores or cylindrical components.

- Grinding: Achieving fine surface finishes and precise dimensions by using abrasive tools.

Heat Treatment:

Special processes like carburizing, quenching, and tempering are often integrated into precision machining to enhance material properties such as hardness, strength, and wear resistance.

CNC Programming:

Computer Numerical Control (CNC) systems are used to automate machining processes, enabling the production of complex components by following detailed digital designs. CNC allows multi-axis operations, ensuring precision in multiple dimensions.

Applications:

Precision-machined parts are critical for industries such as:

- Aerospace

- Automotive

- Medical Devices

- Electronics

- Energy

This process ensures the production of components that meet exacting standards for OEMs and system integrators, serving diverse end-markets with unparalleled quality and reliability. Let me know if you need a detailed write-up or visualizations!