Soluble Wax Core

A soluble wax core typically refers to a material used in various manufacturing processes, particularly in the creation of complex, hollow, or intricate components. These cores are made from wax-like materials that are designed to dissolve in specific solvents or under certain conditions, leaving behind the desired shape or structure.

Applications:

- Investment Casting: In the investment casting process, a soluble wax core can be used to create hollow parts or cavities within metal castings. The core is placed inside a mold, and once the mold is cast, the core can be dissolved (usually in hot water or another solvent) to leave the hollow space. This is often used in industries like aerospace or medical device manufacturing where complex internal geometries are required.

- Prototyping: Soluble wax cores can be used in rapid prototyping techniques. Since the core material dissolves, it allows for the creation of highly detailed and intricate parts without the need for complex post-processing or manual labor to remove the core.

- Plastic Molding: Soluble wax cores are also employed in plastic molding applications, where a similar process is used to create hollow sections in plastic parts. After the molding process, the wax core dissolves to create the necessary voids.

Advantages:

- Complex Geometries: Soluble wax cores enable the creation of parts with complex internal features that would be difficult to achieve using traditional methods.

- Time Efficiency: The dissolvable nature of the core can save time compared to mechanical removal or machining processes.

- Precision: The core material can be engineered to dissolve in a controlled manner, ensuring that the final product is precise.

Dissolution Process:

The process of dissolving the wax core typically involves the following steps:

- Heating: The wax is melted and poured into a mold to form the core.

- Casting or Molding: The core is then used in the production of the final part, either by investment casting or in a molding process.

- Dissolution: After the part has been formed, the core is dissolved by exposing it to a solvent like water, heat, or specific chemical agents, depending on the type of wax used.

Soluble wax cores are especially useful for manufacturing industries where high precision and intricate internal geometries are necessary.

Ceramic Core

A ceramic core is a type of expendable core used in manufacturing processes, particularly in investment casting, to create complex internal cavities or geometries in metal parts. Ceramic cores are widely used in industries such as aerospace, automotive, and medical devices, where parts require intricate internal shapes that cannot be achieved by traditional molding or machining.

Key Features of Ceramic Cores:

- High Temperature Resistance: Ceramic cores are designed to withstand the high temperatures involved in metal casting, especially when molten metals like titanium, superalloys, and steel are used. This makes them ideal for high-performance applications.

- Strength and Stability: Ceramic cores provide structural stability during the casting process and help retain their shape until the molten metal is solidified around them.

- Complex Geometry: Ceramic cores enable the creation of hollow parts with complex internal features such as cooling channels, internal cavities, or intricate passageways that would otherwise be difficult or impossible to form.

Applications:

- Investment Casting: Ceramic cores are commonly used in investment casting, where they are placed inside a mold and surrounded by molten metal. Once the metal solidifies, the ceramic core is typically removed by processes like high-temperature heating or chemical dissolution. This process is often used to create turbine blades, medical implants, and aerospace components.

- Turbine Blades & Gas Turbines: Ceramic cores are particularly useful in producing turbine blades with internal cooling passages. These cooling channels are crucial for the efficiency and longevity of turbine blades exposed to extreme temperatures in jet engines and gas turbines.

- Medical Devices: In the medical field, ceramic cores are used for creating precision components, such as stents or other implants, where complex internal channels or cavities are necessary.

- Casting of Thin-Walled Parts: Ceramic cores are also used in industries where thin-walled, highly detailed parts need to be cast from metals or alloys.

Ceramic Core Manufacturing Process:

The manufacturing of ceramic cores typically involves several steps:

- Core Design and Creation: The design of the ceramic core is made to match the required internal geometry of the final part. The core can be formed using various methods, including:

- Shell building: The core is made using a slurry of fine ceramic particles, which is applied to a mold and allowed to dry and harden.

- Injection Molding: For more complex designs, ceramic slurries can be injected into molds, and the cores are built up layer by layer.

- Drying and Firing: After the core is formed, it is carefully dried and fired in a kiln. This process increases the strength of the ceramic core and ensures that it can withstand the high temperatures of molten metal during casting.

- Core Insertion: The ceramic core is inserted into the mold cavity before the molten metal is poured in. The metal solidifies around the core, capturing its shape and creating internal features in the final casting.

- Core Removal: Once the casting process is complete, the ceramic core is removed. This can be done through various methods, such as:

- Thermal removal: The core is burned out at high temperatures in an oven.

- Chemical removal: Certain types of ceramic cores are dissolved in an acid or other solvent.

- Mechanical removal: In some cases, the ceramic core can be broken apart manually or mechanically.

Types of Ceramic Materials:

The type of ceramic material used for the core depends on the application and the metals being cast. Common materials include:

- Silica (SiO2): This is the most commonly used ceramic material in casting, especially for metals like steel and aluminum.

- Alumina (Al2O3): Alumina is often used when higher strength or better thermal resistance is required.

- Zirconia (ZrO2): Zirconia-based ceramics are used for casting superalloys and other high-performance metals that require higher resistance to thermal and mechanical stresses.

Advantages of Ceramic Cores:

- Precision and Detail: Ceramic cores enable the creation of highly detailed and intricate internal features that would be difficult or impossible to achieve with traditional methods.

- High-Temperature Performance: Ceramics are heat-resistant and can withstand the extreme temperatures of molten metals, making them suitable for high-performance casting.

- Complex Internal Geometries: They allow for the formation of complex internal cavities, channels, and other features that are essential for specialized components like turbine blades or cooling systems.

- Expendable: Ceramic cores are typically designed to be expendable, meaning they are removed after the casting is complete, leaving behind the desired internal features.

Challenges:

- Brittleness: Ceramic materials are typically brittle, which can make handling and transportation of ceramic cores challenging.

- Cost: The use of ceramic cores can add to the cost of the manufacturing process due to the complexity of producing the cores and the need for specialized equipment.

- Core Removal: Depending on the material used, the process of removing the ceramic core can be time-consuming and may require specific equipment or treatment.

Conclusion:

Ceramic cores play a crucial role in producing complex, high-performance components in industries like aerospace, automotive, and medical device manufacturing. They enable the creation of parts with intricate internal structures, which are essential for ensuring the efficiency, performance, and reliability of advanced machinery, such as turbine blades and heat exchangers. Despite the challenges, their ability to withstand high temperatures and provide precision makes them indispensable for many modern manufacturing processes.

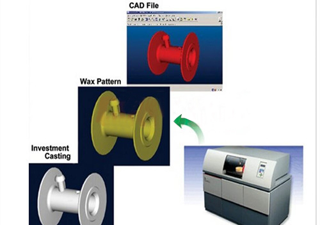

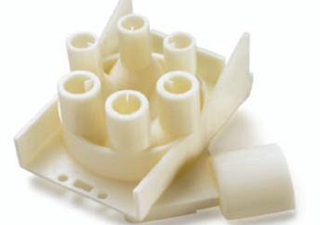

3D printing wax pattern

3D Printing Wax Patterns are a key innovation in the field of investment casting (also known as lost-wax casting), where a wax pattern of the desired part is 3D printed and then used to create a mold. This technique significantly improves the speed, complexity, and cost-efficiency of producing metal parts, especially for industries that require intricate designs or small batch production, like aerospace, jewelry, and medical device manufacturing.

How 3D Printing Wax Patterns Work:

- Design and Modeling: The process starts with creating a 3D digital model of the part. This is done using computer-aided design (CAD) software. The design can be highly complex, including fine details and intricate geometries, which traditional methods might struggle to produce.

- 3D Printing: The 3D design is then sent to a 3D printer capable of printing with a wax-like material. The printer builds the part layer by layer, with each layer being solidified by the printer’s technology (e.g., using stereolithography (SLA) or a similar resin-based technique).

- Post-Processing: Once the pattern is printed, it may require some post-processing to remove excess material, smooth surfaces, or reinforce specific areas. In some cases, a coating of additional wax or resin might be applied to improve the surface finish.

- Shell Creation (Investment Mold): The wax pattern is then coated with a layer of ceramic or another mold material. This is typically done by dipping the pattern into a slurry of fine silica or other refractory materials and then sprinkling it with sand. This step is repeated several times to create a thick, durable mold. The mold is then heated, causing the wax to melt and drain out, leaving behind a hollow ceramic shell.

- Casting: After the wax has been fully removed, molten metal is poured into the mold. The metal solidifies, taking the shape of the original 3D-printed wax pattern. The ceramic shell is then broken away to reveal the final metal part.

- Finishing: After casting, the part may require additional finishing processes like grinding, polishing, or machining to achieve the final desired shape and surface quality.

Advantages of 3D Printing Wax Patterns:

- Complex Geometries: 3D printing allows the creation of highly intricate, detailed, and complex designs that would be difficult, if not impossible, to achieve using traditional wax carving or molding techniques.

- Rapid Prototyping: The 3D printing process is much faster than traditional methods of creating wax patterns, enabling faster prototyping and iterations, reducing time to market.

- Cost-Effectiveness: For low- to medium-volume production, 3D printing wax patterns is cost-effective. It eliminates the need for expensive molds, tooling, or manual labor required to carve wax patterns by hand.

- Customization: 3D printing allows for easy customization of patterns without requiring retooling, making it ideal for low-run, bespoke manufacturing.

- High Accuracy and Precision: 3D printers can create highly accurate wax patterns with fine features and dimensional accuracy, which is critical in industries like aerospace and medical devices where precision is crucial.

- Material Efficiency: There is minimal material waste in the 3D printing process compared to traditional wax patterning, where a significant amount of wax might be cut away or discarded.

Applications:

- Aerospace: Turbine blades, engine components, and other parts with complex internal cooling channels or intricate geometries.

- Jewelry: Custom-designed jewelry pieces, especially those with delicate details, can be efficiently produced using 3D printed wax patterns.

- Medical Devices: Surgical implants and components that require exacting tolerances and customized designs can be fabricated using this method.

- Industrial Parts: Small runs of specialized mechanical or structural parts that require high precision.

- Automotive: Parts with internal features or lightweight structures, such as engine components or exhaust manifolds, can be cast using 3D printed wax patterns.

Materials Used in 3D Printing Wax Patterns:

- Wax-like Resins: These resins are formulated specifically for 3D printers and resemble traditional wax in their consistency, melting point, and ability to form smooth, detailed patterns.

- Castable Resins: Many 3D printers today use castable resins designed for investment casting, which have properties similar to wax and can burn out cleanly without leaving residue.

- Polymer-Wax Combinations: Some 3D printers use combinations of wax and polymer to achieve the desired material properties for investment casting. These blends ensure the pattern is both printable and capable of clean burnout.

Challenges:

- Printer Resolution: The quality of the 3D printed wax pattern is highly dependent on the resolution and precision of the 3D printer. For very fine details, high-resolution printers are required.

- Material Limitations: While the materials used for 3D printing wax patterns have improved, they may still not perform as well in some high-temperature casting scenarios compared to traditional wax patterns.

- Post-Processing: Post-processing steps such as removing supports or smoothing surfaces can add to the time and complexity of the process.

Conclusion:

3D printing wax patterns has revolutionized the traditional investment casting process by offering greater design freedom, faster production, and more cost-effective methods for creating high-precision parts. This technology has particularly impacted industries like aerospace, automotive, medical devices, and jewelry, where complex internal structures or detailed external features are essential. As 3D printing technology continues to evolve, it is likely that the use of wax patterns in casting will become even more widespread, enabling further advancements in design and manufacturing.

Rapid Prototyping

Rapid Prototyping is a development approach used across various industries to quickly create a preliminary version of a product or system. It focuses on building a working model or prototype to test ideas, validate functionality, gather feedback, and refine designs before committing to full-scale production or implementation.

Key Features of Rapid Prototyping

- Speed: The primary goal is to develop a functional version quickly.

- Iterative: Prototypes are refined through multiple cycles based on feedback.

- User-Centric: Focuses on involving end-users early and frequently.

- Low Fidelity to High Fidelity: Starts with simple, low-fidelity models (e.g., sketches, wireframes) and evolves to high-fidelity, functional prototypes.

Benefits

- Early Detection of Issues: Identifies design flaws and usability problems early in development.

- Cost-Effective: Saves resources by reducing rework and avoiding fully developing flawed concepts.

- Enhanced Communication: Provides a visual and functional reference for stakeholders.

- Improved User Satisfaction: Incorporates user feedback throughout the process to align closely with their needs.

Common Methods

- Paper Prototyping: Hand-drawn sketches or simple diagrams to visualize concepts.

- 3D Printing: Used in manufacturing for physical prototypes of designs.

- Software Prototyping: Digital mockups or clickable wireframes for software applications.

- Throwaway Prototyping: Quickly created models intended to be discarded after gathering insights.

- Incremental Prototyping: Building and refining parts of the prototype in stages.

Tools and Technologies

- For Digital Prototypes: Figma, Sketch, Adobe XD, Axure.

- For Physical Prototypes: Tinkercad, Fusion 360, AutoCAD, 3D printers.

- For Software Prototyping: Visual Studio, Unity, low-code platforms like OutSystems.

Rapid Prototyping

Rapid Prototyping